Project Objectives and Implementation Strategies

Project Objectives and Implementation Strategies

Project Objectives and Implementation Strategies

To achieve the goals set by this project, AIM-HI has formulated strategies to recruit outstanding domestic and international faculty and researchers, enhance academic research capacity, deepen smart manufacturing technologies, engage with overseas academic and research institutions in the same field, actively participate in international academic activities, promote international collaboration and exchanges, and establish:

(1) Smart manufacturing applications for carbon-reducing Electric Vehicle Transmission System

(2) Smart manufacturing applications for precision medical of digital healthcare Materials

(3) Smart manufacturing technologies for the processing of key components in semiconductor manufacturing

(4) A carbon footprint monitoring and energy-saving control experimental site for smart manufacturing processes

as well as strengthen international industry-academia-research collaboration networks.

Thus, the concrete implementation strategies are developed in the following aspects: talent cultivation, academic performance, technology development, international cooperation, social contribution, and establishment of important facilities.

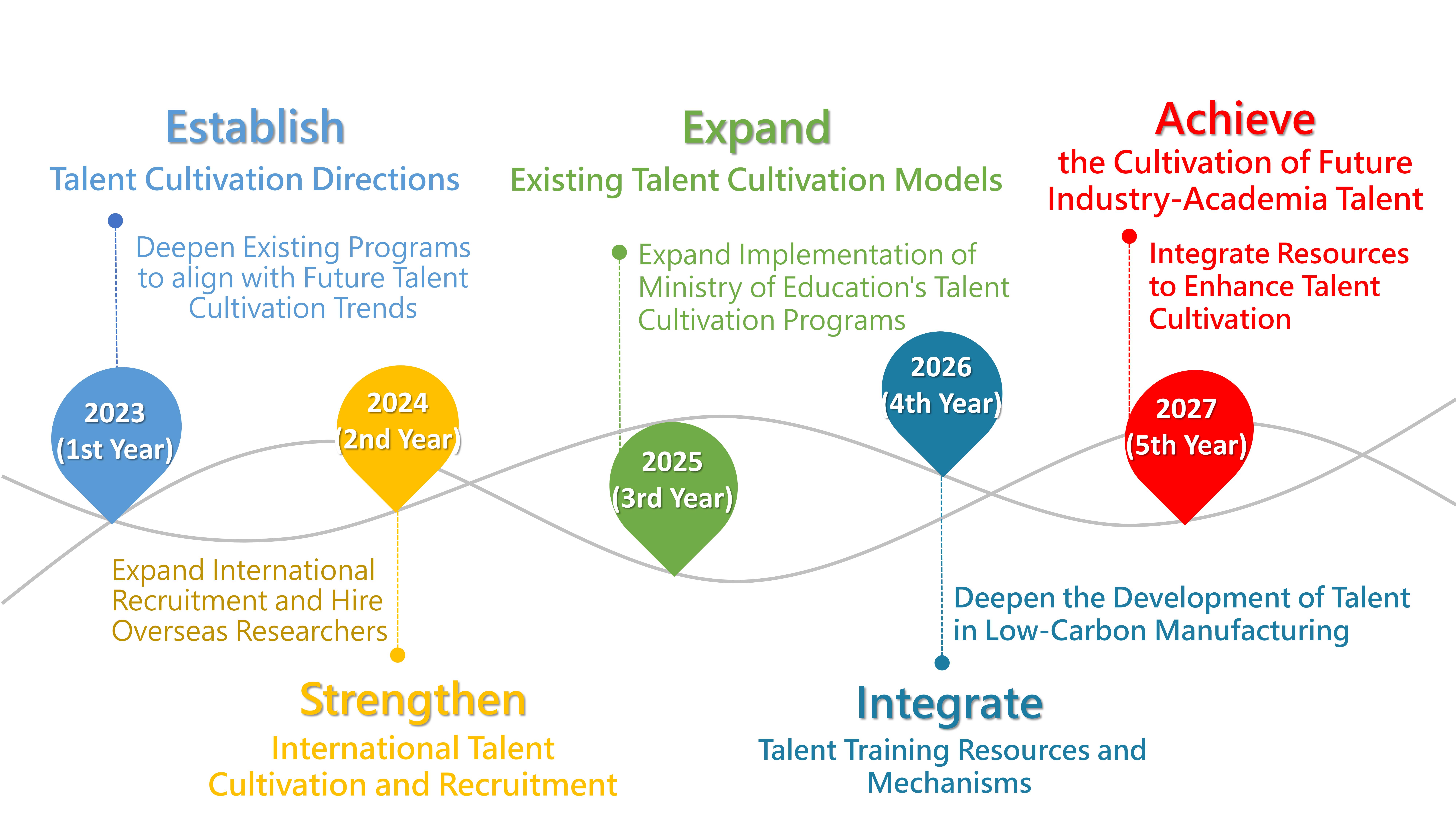

1. Talent Cultivation

In terms of talent cultivation, AIM-HI plans to:

- Short-term: Deepen existing master's/doctoral programs, aligning with future trends in talent development.

- Mid-term: Expand internationally by nurturing and attracting talent, and broadening the existing talent cultivation model by integrating training resources and mechanisms.

- Long-term: Strategically focus on cultivating talent in low-carbon green manufacturing and establish a comprehensive training mechanism.

In terms of implementation strategy:

- Year 1: Continue the first phase's Featured Areas Research Center Program and the ongoing EMI project, deepening existing master's/doctoral courses, to understand future trends in talent cultivation for low-carbon smart manufacturing.

- Year 2: Expand international recruitment and hire international researchers based on Year 1's curriculum planning. Launch interdisciplinary international programs at the college level, co-develop online courses with partner universities, offer mutual credit recognition, and work toward establishing joint international degree programs (mainly at the master's level).

- Year 3: Utilize the Ministry of Education’s talent cultivation program to provide comprehensive resources for students, partners, and research teams who joined in Year 2.

- Year 4: Follow the Year 3 model to deepen efforts in cultivating talent for low-carbon green manufacturing, and establish a comprehensive talent training and retention system.

- Year 5: Actively match the cultivated low-carbon smart manufacturing R&D talent with domestic industries to promote industrial application and enhance industrial competitiveness.

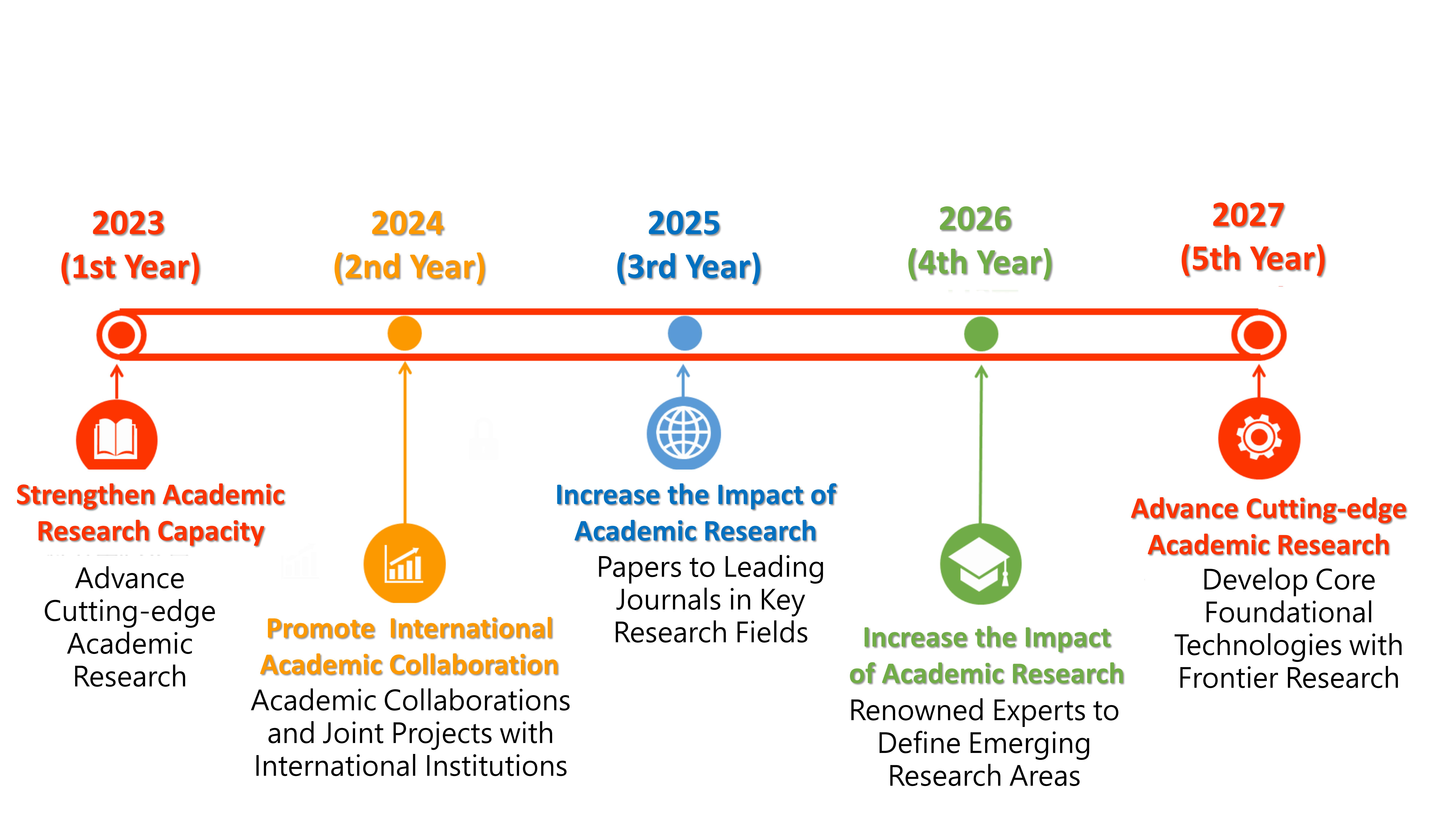

2. Academic Performance

In the area of academic research, AIM-HI will:

- Short-term: Encourage full-time personnel to improve both the quantity and quality of published papers and submit papers to interdisciplinary and high-impact journals.

- Mid-term: Activate international academic collaborations by co-publishing journal papers and conducting bilateral research projects with international scholars to enhance global visibility.

- Long-term: Increase the international influence of academic research through faculty participation as committee members or as editors of international journals.

For implementation strategy:

- Year 1: Encourage full-time personnel to improve the quantity and quality of publications and initiate exchanges with international university laboratories.

- Year 2: Progress to collaborative research and co-publication with international scholars, and propose Joint cooperation projects.

- Year 3: After increasing AIM-HI’s international academic exposure, further enhance its influence through the number of Q1 journal publications and serve in key roles within international academic institutions.

- Year 4: After securing a strong foundation in current fields, AIM-HI will consult with an International Advisory Board to receive expert recommendations and identify advanced research areas to expand academic horizons.

- Year 5: While maintaining current academic research capacity, AIM-HI will also begin developing the identified advanced field and key technologies to continuously strengthen research capability and influence.

3. Technology Research and Development

The Center will deepen the "smart manufacturing technologies" established during the first phase, which include information security, artificial intelligence, human-machine collaboration, sensing technologies, multi-axis precision machining in hybrid manufacturing, 3D printing, precision measurement, as well as industrial applications such as digital healthcare and gear surface optimization. In response to the global trend of net-zero emissions and Taiwan’s future technological development priorities, the Center has set development goals for advanced technologies in electric mobility, unmanned vehicles, precision medicine, semiconductor processes, and low-carbon green manufacturing:

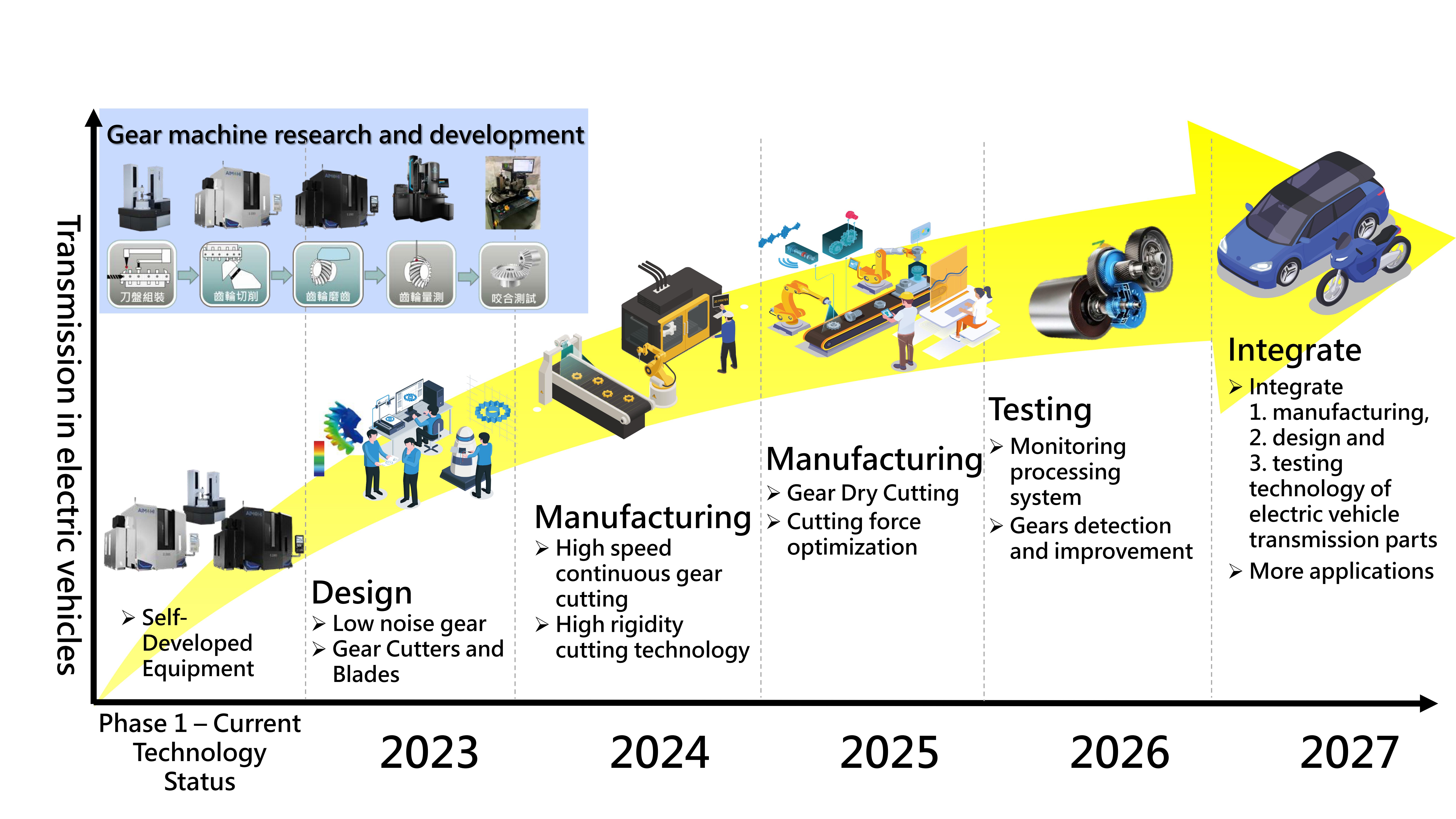

(1)Electric Mobility:

Currently, Center members are conducting research on the design and manufacturing of transmission components for electric vehicles in collaboration with companies such as Hota Industrial and Welltech Electric, and have received seed funding from the National Science and Technology Council to develop smart tool holder technology. In the future, the Center will focus on integrating smart tool holders with additive-subtractive 3D printing technology, and establish CNC-based multi-axis smart machining platforms for gearboxes and components used in electric and unmanned vehicles. Key technologies include:

- Composite material 3D lattice structure printing

- Five-axis simultaneous machining using smart tool holders

- Intelligent additive-subtractive manufacturing

- Silent gear surface grinding

- Gearbox inspection techniques

These technologies will support the design and manufacturing of components for electric mobility with high-speed and high-torque requirements, as well as high-strength parts for unmanned vehicles. The Center will work closely with industry partners to provide smart machining technologies and inspection services. The diagram below illustrates the current technological capabilities and future goals in electric mobility.

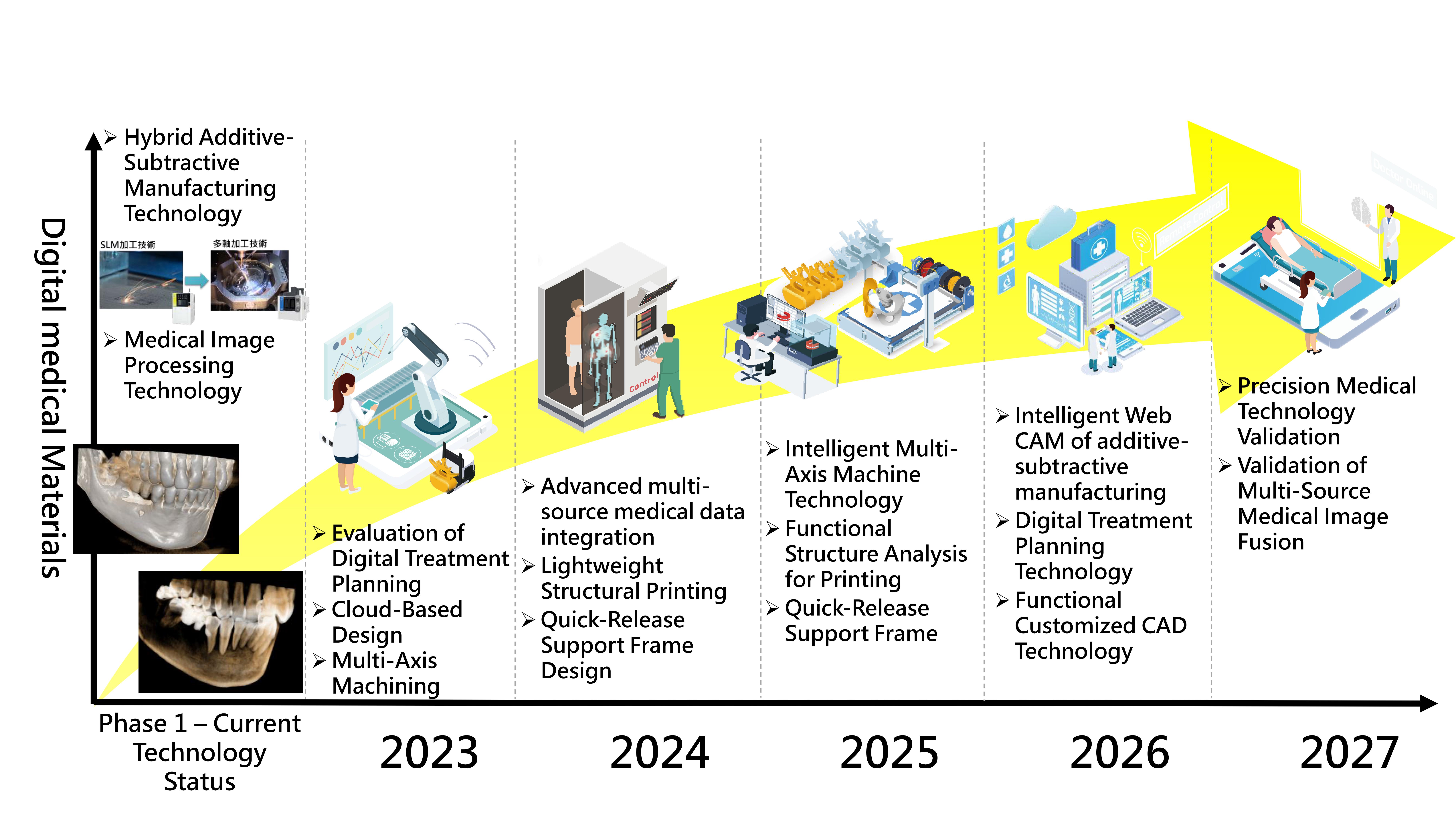

(2)Digital Medical Devices:

Members of the Center have previously collaborated with nearby medical institutions such as Chiayi Christian Hospital, Dalin Tzu Chi Hospital, and Chi Mei Hospital in Tainan to develop precision medical devices and healthcare technologies. In the future, the Center aims to integrate medical imaging with 3D printing and CNC multi-axis machining to establish advanced medical services and affordable customized self-pay medical products. Key technologies include:

- Advanced multi-source medical data integration

- Functional customized CAD

- Intelligent additive-subtractive Web CAM

- Precision digital treatment planning services

- Surgical procedure simulation

These technologies will enable the provision of precision medical services and affordable customized medical products in the Chianan region. With Southern Taiwan as the foundation, the Center will expand toward Southeast Asia, offering high-end medical planning and medical product design and manufacturing services. The diagram below illustrates the current technical status and future goals of the Center in the field of digital medical devices.

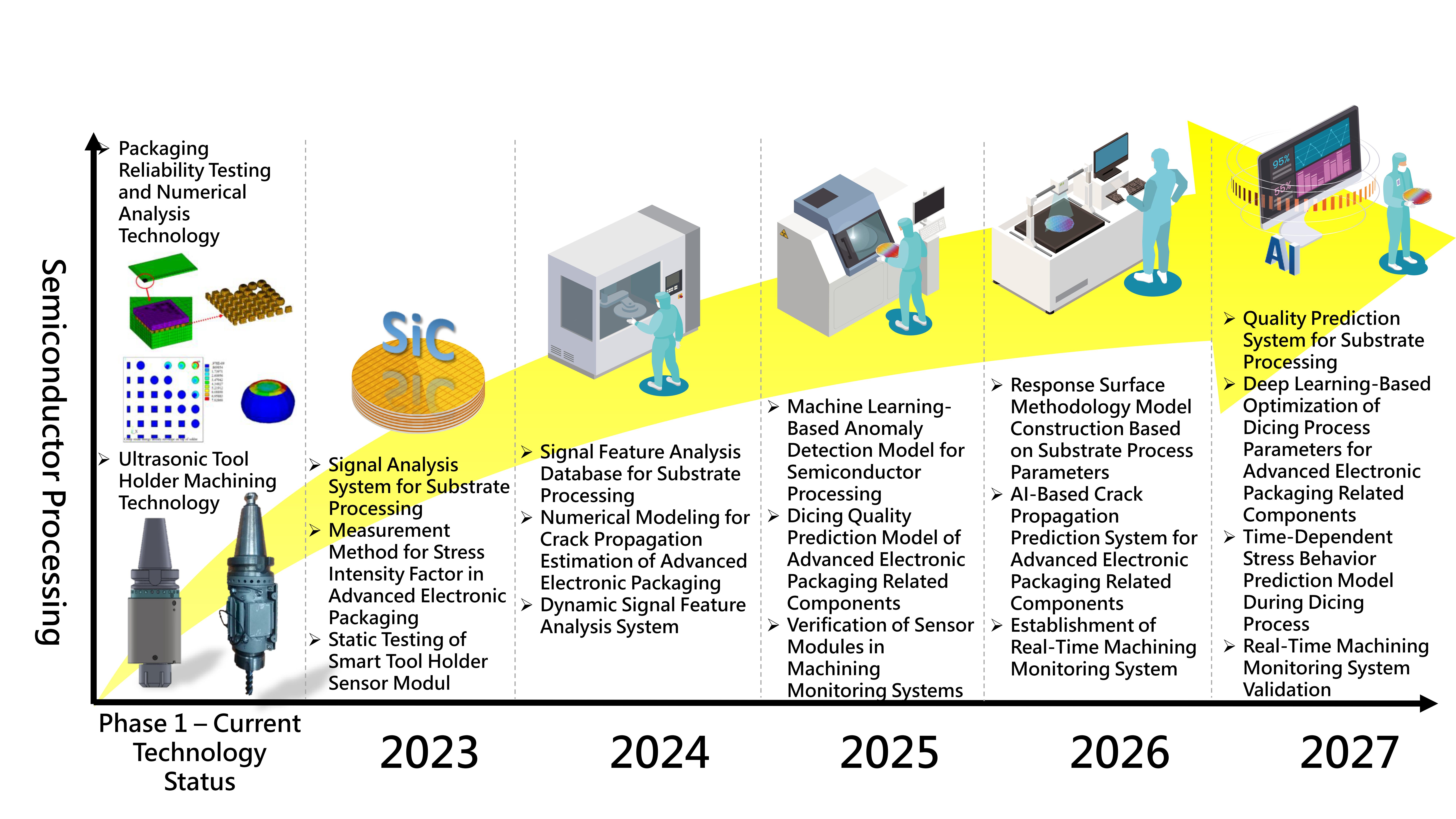

(3)Semiconductor Manufacturing Processes:

Currently, members of the Center are conducting research in collaboration with major domestic semiconductor companies, such as GlobalWafers and ASE Group, focusing on semiconductor process machining. Looking ahead, the Center will target semiconductor product processes, semiconductor materials, and process equipment machining to develop a digital twin cyber-physical integration system. Key technologies include:

- Development of intelligent diagnostic technology for advanced semiconductor substrate processing

- Development of virtual-real integration optimization for advanced packaging processes

- Development of intelligent monitoring systems for advanced semiconductor machining

- Development of high-efficiency AI predictive models for vertically integrated semiconductor processes

These technologies are expected to provide concrete recommendations and optimization strategies for evaluating the implementation of future advanced process equipment and improving process yields, thereby supporting the development of next-generation semiconductor component manufacturing technologies. The diagram below shows the current status and future goals of the Center's precision semiconductor processing technologies.

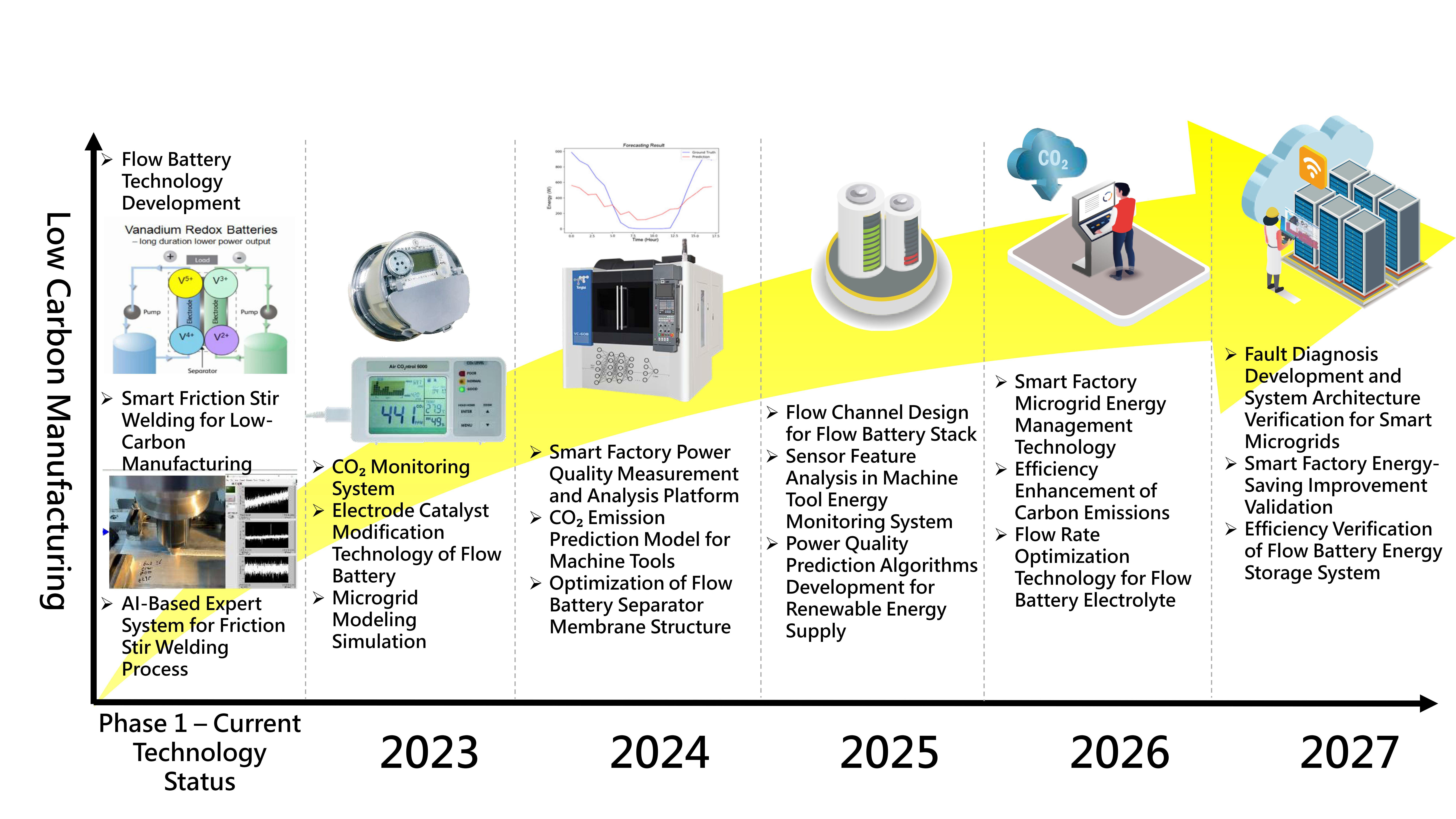

(4)Low-Carbon and Green Technologies:

Currently, the Center's members are conducting research on green manufacturing in collaboration with major domestic smart manufacturing companies such as Tongtai Machine & Tool, YCM (Yeong Chin Machinery), and Hartford (Fair Friend Group). In the future, the Center will build a comprehensive low-carbon, energy-saving, and carbon footprint monitoring demonstration site, based on the smart factory demonstration production line developed by the featured research center. Key technologies include:

- Machine tool energy consumption and carbon emission monitoring systems

- Smart factory process planning integrated with time-of-use electricity pricing and efficiency operation strategies

- Development of electrocatalyst materials and stack designs for flow battery energy storage systems

- Development of smart factory microgrid systems for renewable energy, including energy management and diagnostic technologies

These technologies will initially be offered as services to Taiwan’s machining and manufacturing industries. The diagram below illustrates the current status and future objectives of the Center's low-carbon and green technology initiatives.

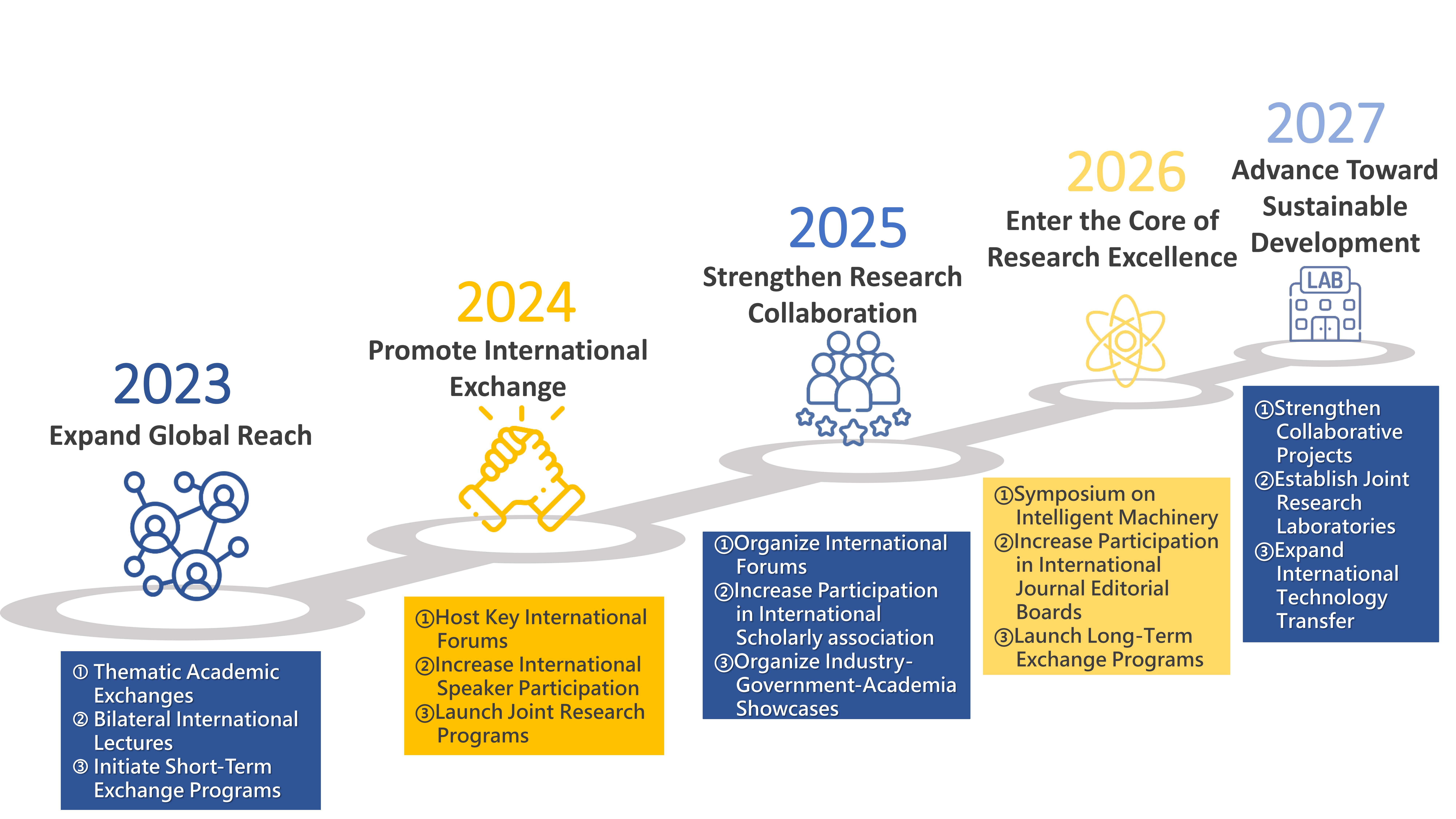

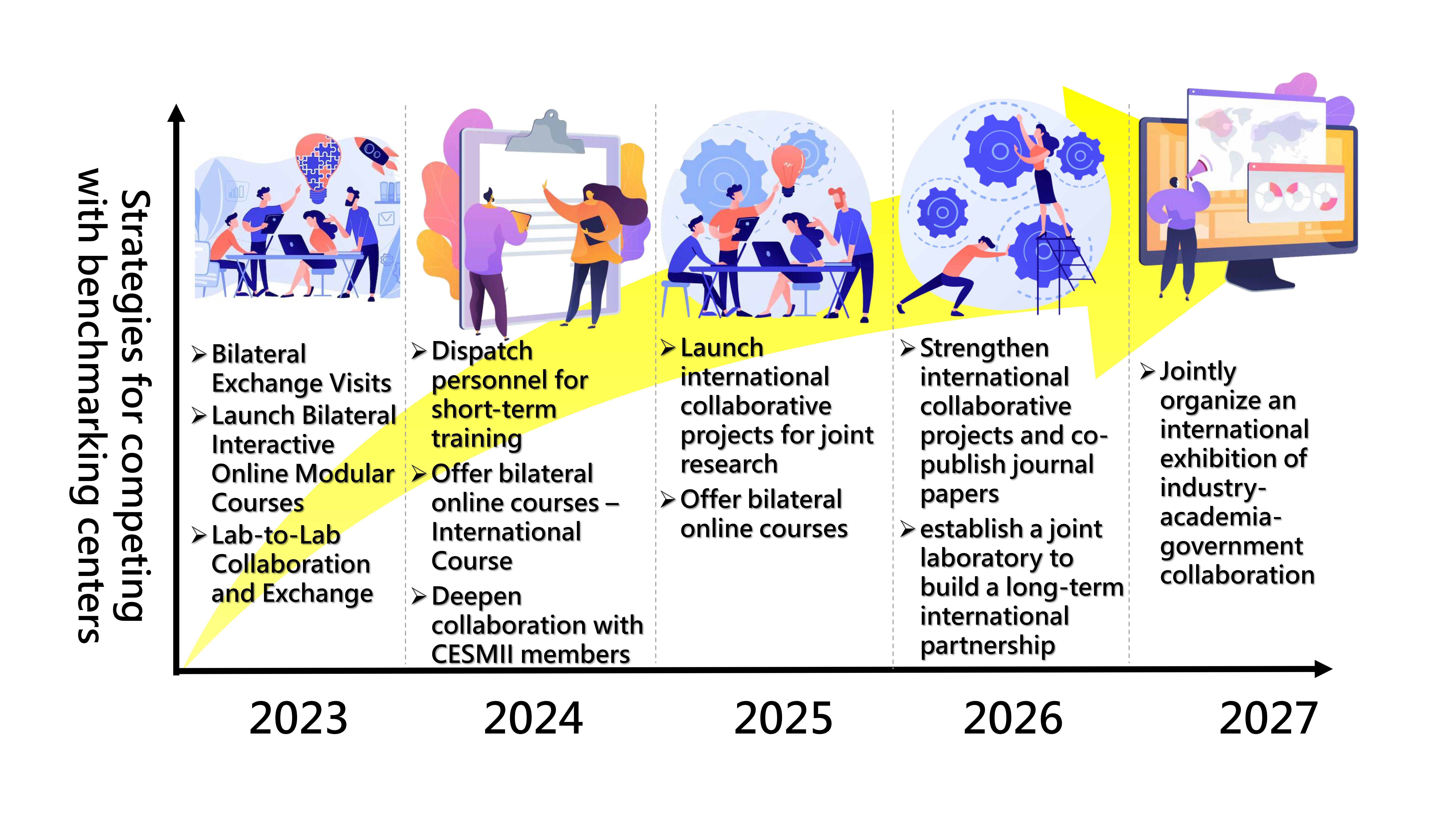

4. International Collaboration

In the area of International Collaboration, AIM-HI will:

- Short-term: Promote academic exchanges and short-term bilateral visits related to future development themes with current international partners.

- Mid-term: Leverage domestic resources to co-host international exhibitions across industry, government, and academia with international partners and their affiliated enterprises, thereby fostering long-term cooperation

- Long-term: Aim to become a member of prominent international societies and serve as editors of academic journals to raise its global visibility, and to establish joint laboratories to ensure sustainable international engagement

For implementation strategy:

- Year 1: Expand international collaboration through guest lectures and short-term exchange programs.

- Year 2: Based on the established foundation, bilateral collaborative projects will be launched, and key forums will be hosted to deepen the frequency and substance of exchanges.

- Year 3: Continue building on previous achievements by hosting international forums and exhibitions of academia-industry-government collaboration outcomes, to enhance the international academic standing of faculty members.

- Year 4: Increase the proportion of journal editors and initiating long-term exchanges with overseas partner university and participate in the New Southbound Policy.

- Year 5: Based on the contributions of the past four years, AIM-HI will aim to establish joint laboratories and expand international technology transfers, and move toward sustainable development.

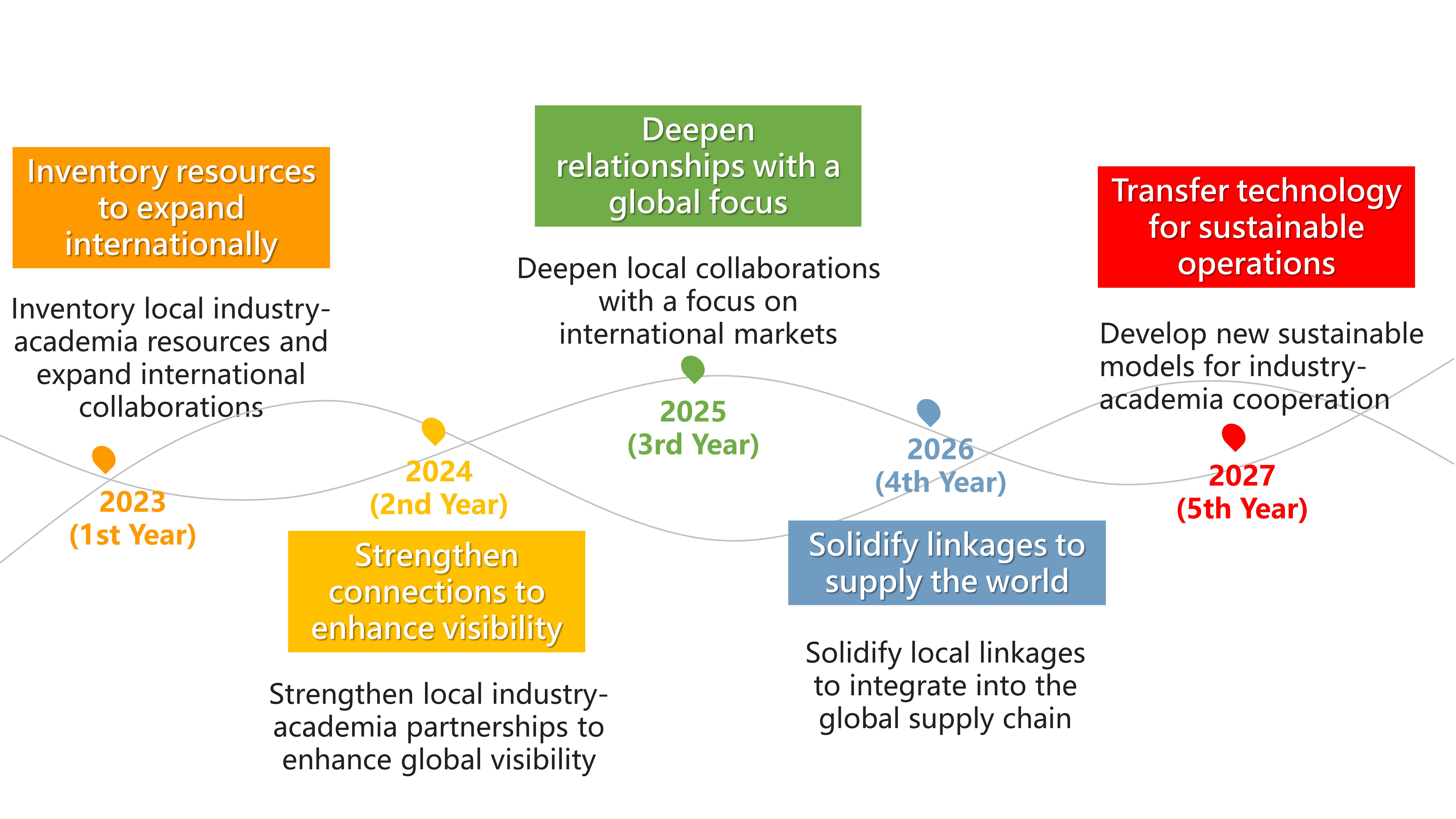

5. Social Contribution

In the area of social contribution, AIM-HI will:

- Short-term: Assess the local industry-academia resources, expand international industry-academia connections, and establish mechanisms for technology commercialization.

- Mid-term: Deepen local industry-academia collaboration, target international markets, and promote the commercialization of R&D results.

- Long-term: Aim to strengthen local industry-academia linkages, strive to become part of the global supply chain, and enhance the level of technology application.

For implementation strategy:

- Year 1: Assess industrial needs in nearby industrial parks and science parks and consolidate the research capabilities.

- Year 2: Based on the findings from the first year, then plan to establish production pilot run phase sites, seek opportunities for commissioned testing services, and invigorate local industry-academia collaboration.

- Year 3: Continue building on previous achievements by hosting international forums and exhibitions of academia-industry-government collaboration outcomes, to enhance the international academic standing of faculty members.

- Year 4: Plan to establish product-oriented, interdisciplinary research teams and strategic alliances to consolidate R&D capabilities and offer more comprehensive technical consulting and services to industry, maximizing the synergistic benefits of industry-academia collaboration.

- Year 5: A sustainable development task force will be established to maintain an ongoing industry-academia operational model through deep collaborations such as technology transfers and joint project applications with industry.

6. Benchmarking Center

In the short term, AIM-HI aims to target the Smart Manufacturing Innovation Center (SMIC) at North Carolina State University (NC State) as a benchmark. By learning from this benchmarking center, both parties will engage in technical cooperation, co-publish journal papers, exchange faculty, students, and researchers, and organize international advisory boards and forums, all aimed at improving the world university rankings in CCU. In the medium term, AIM-HI will visit the CESMII (Smart Manufacturing Innovation Institute) member universities to understand their technical development directions and application domains, and organize workshops focused on specific topics to facilitate practical exchanges. In the long term, AIM-HI aims to help Taiwanese enterprises join the U.S. manufacturing supply chain by engaging in international industry-academia cooperation with U.S. manufacturers. AIM-HI will target the Smart Manufacturing Innovation Center (SMIC) at NC State as a benchmark. The goals and strategies for pursuing this benchmark are outlined below for the short, medium, and long terms:

- Short-term(2024-2025): In the first and second years, AIM-HI will enhance cooperation with partners in smart manufacturing and related fields through bilateral visits and Lab-to-Lab exchanges. This will promote knowledge sharing and technical collaboration, laying a foundation for future cooperation. Additionally, AIM-HI will launch online basic courses jointly with NC State, fostering international research and technical talent, thereby enhancing academic levels and professional capabilities. Furthermore, AIM-HI will expand its exchange and cooperation with other CESMII member universities, further strengthening overall research capabilities, promoting smart manufacturing development, and driving global technological innovation.

- Mid-term(2026): Building on the cooperation relationships and research achievements from the past two years, AIM-HI will formally initiate deeper and more extensive international collaboration projects. These projects will deepen both parties' academic research and technological innovation in smart manufacturing. AIM-HI will continue to offer the online basic courses introduced in the second year and introduce online thematic courses focused on the four major technology research, promoting academic development in smart manufacturing. These courses aim to jointly cultivate international research and technology talent, fostering global technological innovation and laying a solid foundation for future academic and technical cooperation.

- Long-term(2027-2028): AIM-HI will further strengthen cooperation with partners, aiming to jointly publish high-level academic papers in leading smart manufacturing journals, promoting international recognition of research outcomes. Additionally, AIM-HI will actively seek to establish joint laboratories to lay a solid foundation for long-term collaboration and enhance experimental and technical capabilities in smart manufacturing. And also leverage the combined industrial resources of both parties to showcase the abundant results of international cooperation, expanding the global influence of the smart manufacturing sector and promoting multinational research and applications, contributing to the development of global manufacturing industry.

7. Establishment of important facilities

AIM-HI integrates relevant technical laboratories on campus to establish smart components and individual smart machines, which will be further integrated into smart intelligence manufacturing experimental fields. These establishment will provide experimental platforms for research development across various domains. Over the past five years, the following five major experimental teaching fields have been established:

- Machine Tool AIMC Smart Manufacturing Unit Technology Display Field

- Gear Closed-loop Smart Manufacturing Technology Display Field

- Human-Machine Collaboration VR/AR Display Field

- Metal and Composite 3D Printing Display Field

- AI Friction Stir Welding Process System Display Field

In the next five years, as the Phase 2 of the Higher Education SPROUT Project, AIM-HI will enhance the existing IT security environment to build a comprehensive OT field control and cybersecurity environment. This development will support the four major areas of focus:

- Application of smart manufacturing technology in electric vehicles and intelligent unmanned vehicles to reduce carbon emissions.

- Application of smart manufacturing in the manufacturing and processing of medical devices for precision healthcare.

- Application of smart manufacturing in precision machining for semiconductor processes.

- Green manufacturing systems focused on carbon reduction in manufacturing processes, aiming for net-zero carbon emissions

Currently, AIM-HI has 10 core feature laboratories and has continuously added 2-3 unique experimental fields over the past three years. These include:

- "Machine Tool AIMC Smart Manufacturing Unit Technology Display Field I"

- "Smart Manufacturing Gear Experiment Display Field I"

- "Human-Machine Collaboration VR/AR Display Field"

- "Metal and Composite 3D Printing Display Field"

- "Friction Stir Welding Process Technology and International Collaboration Display Field"

In the future, AIM-HI plans to integrate resources from industry, academia, and research to establish at least 8-10 core feature laboratories and 5-6 smart machinery display fields. In response to research and incubating startup team demands, AIM-HI plans to establish four major thematic spaces over the next five years, including:

- "Green Low-carbon Electric Vehicle and Autonomous Vehicle Experimental Field"

- "Digital Medical Device Processing Experimental Field"

- "Industrial Control Information Security Certification Experimental Field"

- "Semiconductor Smart Manufacturing Process Experimental Field"

621301 Innovation Building R209, 168 University Road, Ming-Hsiung Township, Chia-Yi 621, Taiwan, ROC

621301 Innovation Building R209, 168 University Road, Ming-Hsiung Township, Chia-Yi 621, Taiwan, ROC Tel:(05)2720411#16464 | Fax:05-272-1101

Tel:(05)2720411#16464 | Fax:05-272-1101 E-mail:aimhi@ccu.edu.tw

E-mail:aimhi@ccu.edu.tw