Benchmarking Center

Benchmarking Center

Benchmarking Center

In 2024, AIM-HI actively engaged with benchmarking center laboratories that have previously collaborated closely with us. A variety of in-person and virtual exchanges were conducted, culminating in the successful achievement of our benchmarking center objectives. Details are as follows:

1. Regular Online Exchanges and MOU Signing with SMIC Smart Manufacturing Research Center:

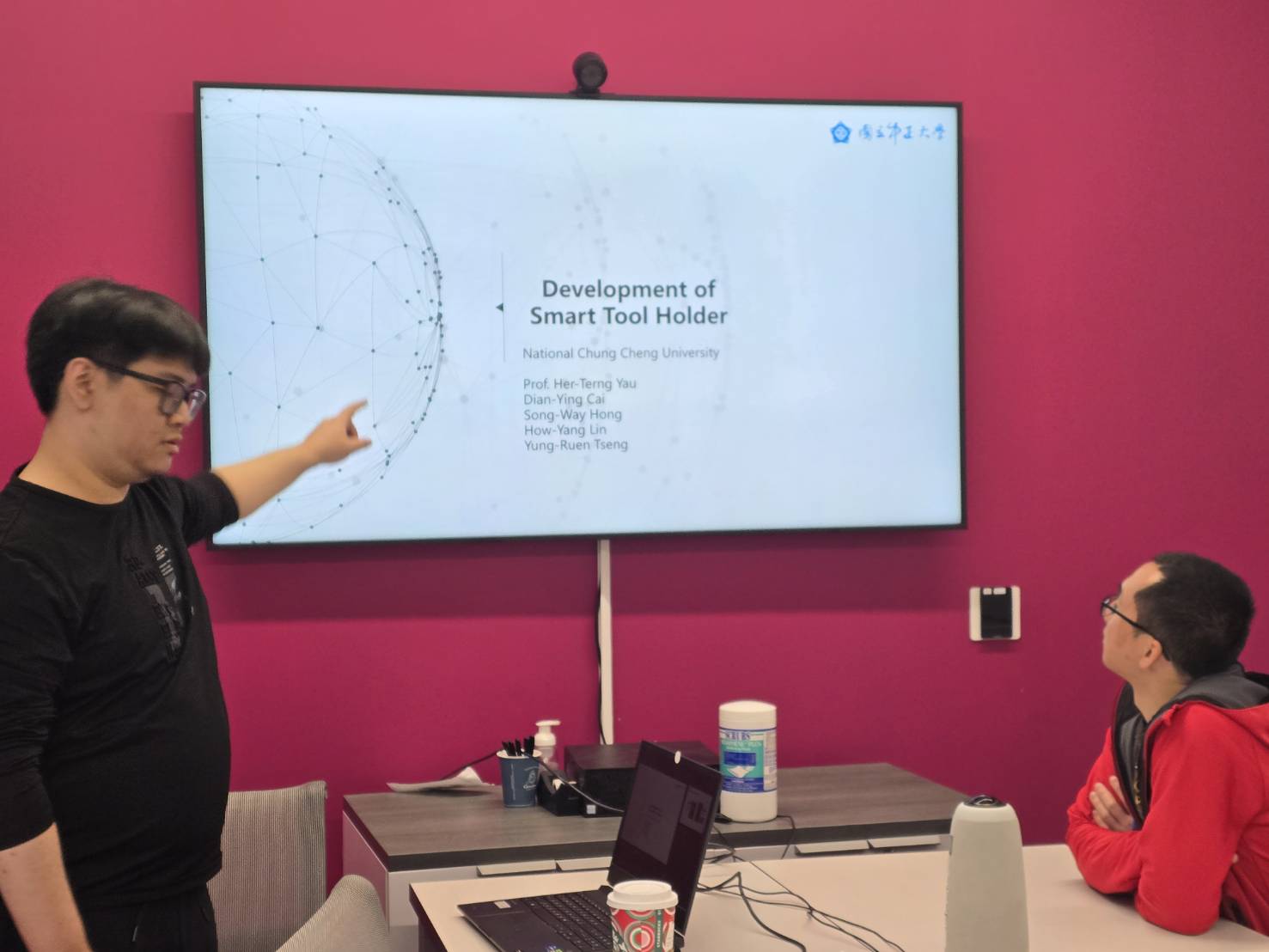

AIM-HI maintained ongoing virtual academic exchanges with researchers from the SMIC Smart Manufacturing Research Center at NC State University, delving into advanced technologies in the smart manufacturing domain. In regular meetings, Professor Yuan-Shin Lee, former director of SMIC, shared his research in biomedical manufacturing, computational geometry, integrated CAD/CAM/CAE, and 5-axis sculptured surface machining. As a result of these discussions, a 3-year MOU for research collaboration was signed between our Artificial Intelligence and System Control Lab led by Professor Her-Terng Yau and Professor Lee’s Advanced Manufacturing Lab, focusing on applications of smart tool holders. The MOU outlines key areas of technical exchange and strengthens the foundation for long-term international academic cooperation, advancing collaboration in education, research, and technological innovation in smart manufacturing and related fields.

2. Short-Term Research Visit to Benchmark Center: Lab-to-Lab Collaborative Project:

In 2024, a doctoral student from Professor Yau’s team was sent to NC State University for a short-term research visit, focusing on sensor technology applications in smart manufacturing. The visit emphasized integrating smart tool holder, image, and vibration sensing technologies for metalworking. Aim-HI developed mechanical models using smart tool holders to predict cutting force, tool wear, and chatter, enhancing machining accuracy and stability. Meanwhile, NC State applied imaging and vibration sensing for anomaly detection and quality control. Both sides shared technical reports and data, exploring the synergy of multi-sensor applications to overcome limitations of single-sensor approaches. Outcomes include validated technical integration, data sharing, and theoretical complementarity, laying a solid foundation for future collaboration. Both parties will continue to refine sensor data fusion models and advance automation and intelligence in smart manufacturing.

3. Joint Online Courses to Promote Talent Development:

In collaboration with Professor Xiaolei Fang of the Edward P. Fitts Department of Industrial and Systems Engineering at NC State, a series of bilateral online courses were conducted under the theme: “Statistical Learning Methods for System Condition Monitoring with Applications in Advanced Manufacturing.” The course introduced statistical learning applications in industrial fault diagnosis and failure time prediction, using real-world case studies to illustrate challenges and solutions. In addition, Professor Ping-Huan Kuo from Department of Mechanical Engineering offered a course on “AI-Based Control Methods for Robots”, expanding participants’ knowledge in smart manufacturing. A total of 35 students participated in this four-session course series, aimed at cultivating talents and enhancing AIM-HI’s international research capacity.

4. Expanded Collaboration with Leading U.S. Universities within the CESMII Ecosystem:

In addition to comprehensive exchanges with our designated benchmarking center, we also continued strategic engagements with other CESMII ecosystem member universities, including UCLA and Purdue University:

- University of California, Los Angeles (UCLA):Professor Shih-Lueh Chen has maintained close collaboration with Professor Tsu-Chin Tsao in the field of mechatronics and control, focusing on aerospace component thin-shell machining. In 2024, Professor Chen sent a doctoral student to Professor Tsao’s lab for a short-term research visit aimed at integrating robotic-assisted machining and chatter suppression technologies into aerospace manufacturing in Southern California. Both professors plan to co-author a paper for the International Journal of Machine Tools and Manufacture to advance the field further.

- Purdue University:AIM-HI actively collaborated with Purdue University to enhance international academic strength in smart manufacturing. In 2024, Professor Martin Byung-Guk Jun from Purdue’s School of Mechanical Engineering and a member of its Smart Manufacturing Innovation Center (SMIC), visited AIM-HI. Professor Jun, an expert in intelligent diagnostics for machine tools with over 260 published papers, delivered a keynote titled “Towards Autonomous Manufacturing with Digital Twins and Smart Robotics for Manufacturing.” He shared his latest research on autonomous manufacturing systems. In addition, a Memorandum of Understanding (MOU) was signed between our Center and Purdue’s College of Engineering to pave the way for future academic collaborations.

621301 Innovation Building R209, 168 University Road, Ming-Hsiung Township, Chia-Yi 621, Taiwan, ROC

621301 Innovation Building R209, 168 University Road, Ming-Hsiung Township, Chia-Yi 621, Taiwan, ROC Tel:(05)2720411#16464 | Fax:05-272-1101

Tel:(05)2720411#16464 | Fax:05-272-1101 E-mail:aimhi@ccu.edu.tw

E-mail:aimhi@ccu.edu.tw