Project name:

Developing a 5-axis numerical control hypoid gear processing machine for heavy cutting by using smart manufacturing and a virtual–physical integration system.

Principal investigator:

Prof. De-Shin Liu, director of the Advanced Institute of Manufacturing with High-Tech Innovations (AIM-HI), National Chung Cheng University

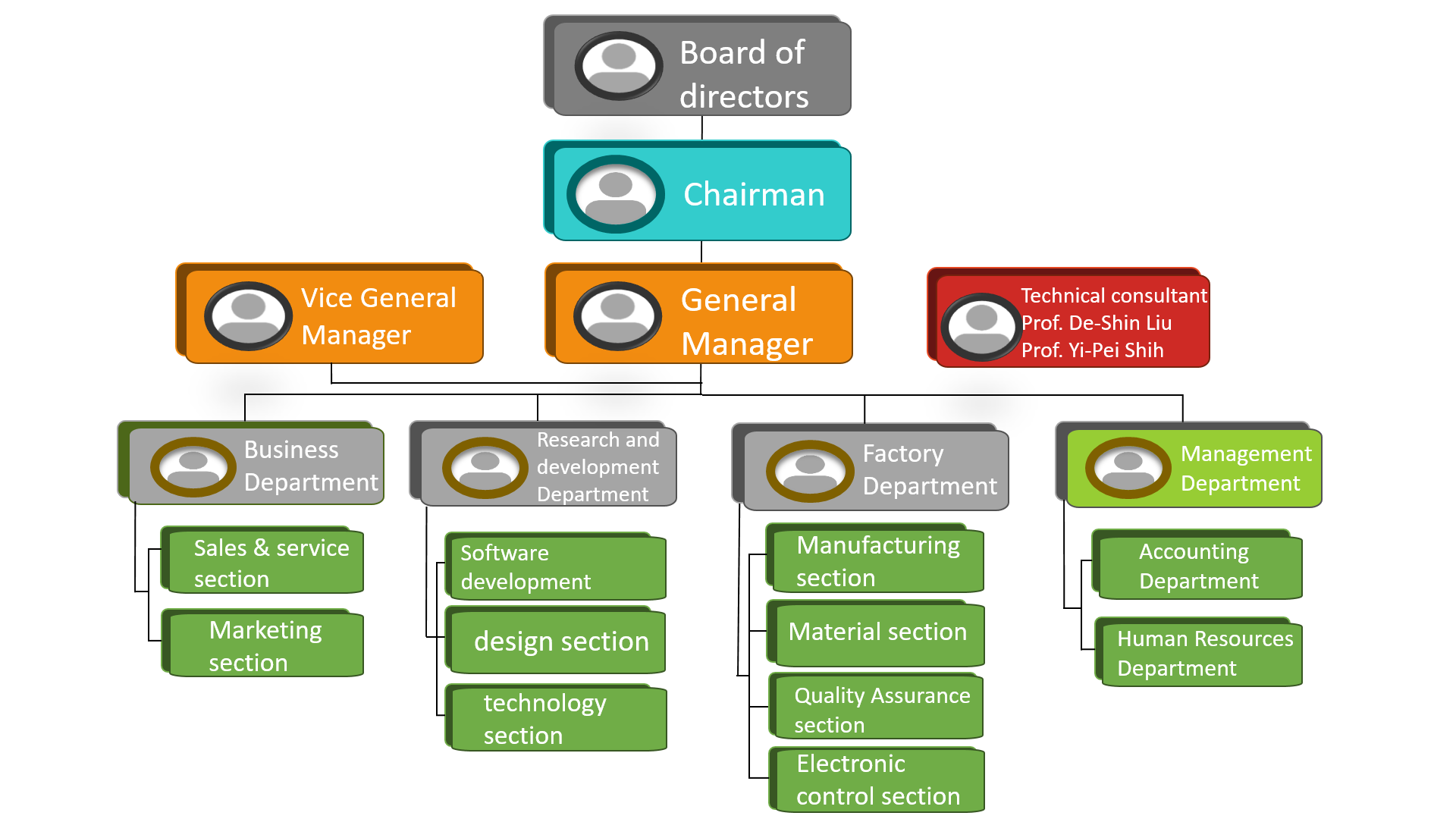

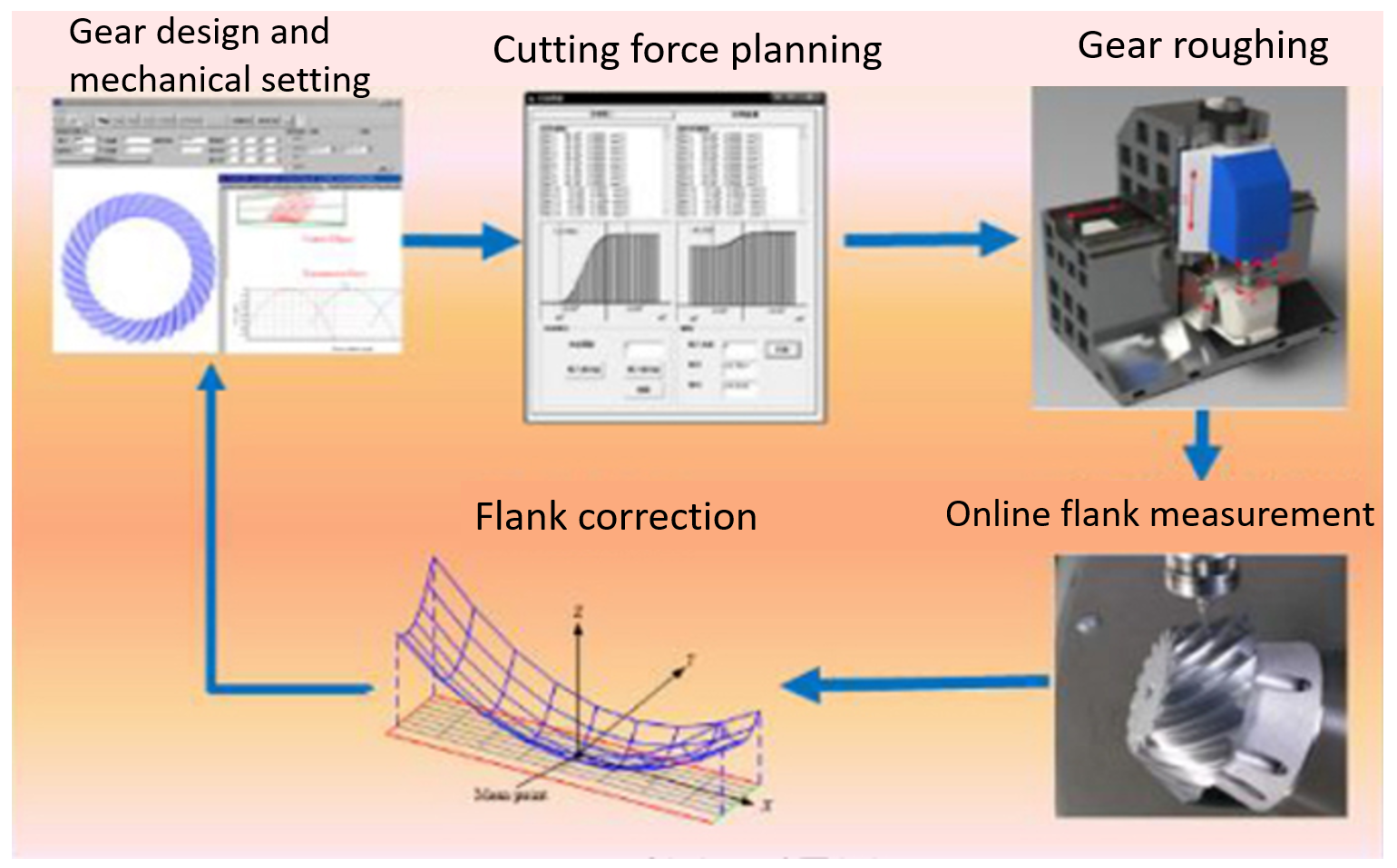

This value creation project aims to develop a smart machine-based innovative hypoid gear processing machine. The research team includes legal persons and scholars from various universities who have more than 15 years of experience in whole-machine and component design and analysis. By using key technologies such as the double-sided double gear-cutting method, standing machine design, smart numerical control paths, adaptive cutting force, and a virtual–physical integration system, the research team proposed the development of a human–computer interface featuring the same level of processing accuracy and user friendliness as other human–computer interfaces but at a lower cost, allowing it to enter the market.

1 By using the engineering theories of bevel gear processing technology proposed by the CCU team and the precision machinery design experience of legal persons units, the project team can create and integrate the sensors and actuator device system required in smart machinery.

2 A virtual–physical integration system is also established, with which the product can be connected to the main cloud system in the aspects of regional networking, real-time monitoring of operational schedules, big data analysis, and health status diagnosis based on long-term use. Therefore, this project proposes to develop a 5-axis numerical control hypoid gear processing machine for heavy cutting using smart manufacturing and a virtual–physical integration system.

![]() Project Team

Project Team

![]() Project Objectives

Project Objectives

This project intends to develop a standing hypoid gear cutting and grinding machine. From product development, key resource acquisition, supply chain establishment, production technique development, trial and mass production, and eventually to product selling on the market, this project develops a three-stage operational plan (short-, mid-, and long-term plans), whose operational milestones are presented in the following table. The short-term goals in the initial stage of 2017–2018 are to complete the development of a vertical hypoid gear processing machine, establish key technologies to enhance the threshold for competition, and establish a supply chain of external cooperating manufacturers for the gear processing machine by assessing these manufacturers’ techniques, quality, and ability to complete tasks on time in the process of machine development. The mid-term goals during 2019–2020 are to produce a vertical hypoid gear grinding machine. Also, fundraising and startup of the company can be expected in the stage. The 2 machines will be demonstrated in Taipei International Machine Tool Show (TIMTOS) 2019 in order to catch the attention of investors.The long-term goals to be completed during 2021–2022 are to establish an technical service center in the first year of the start-up company.

| Operational goals | Initial stage | Mid-term stage | Long-term stage |

|

- Product development: 5-axis numerical control hypoid gear processing machine - Acquisition of key resources - Supply chain establishment |

- Development of product accessories: hypoid gear tool sharpener - Production technique development - Pricing strategy |

- Establishment of an postsale service and technical service center - Become part of a world-famous automobile component supply chain - Customer management |

|

| Milestones |

2017- Complete the mechanical setup of the computing software and the development of the human–computer interface - Complete mechanical design of the standing hypoid gear

|

2019- Produce the hypoid gear grinding machine - Participate in TIMTOS 2019 - Operating the startup company and fundraising capital from investors |

2021- Establish an technical service center - Reach an estimated annual revenue of NT$ 250 million

|

2018

- Complete development of the hypoid gear processing machine - Complete verification of the closed-loop manufacturing system by cutting tests - Technical indicators: Complete development of the hypoid gear cutting machine 1.Accuracy ≥ DIN6 2.Maximum cutting capacity = 6.5 modulus; max working diameter up to280 mm |

2020- Complete accuracy and reliability verification for the hypoid gear grinding machine - Establish a demosite for hypoid gear processing - Establish an agency system for the startup company - The first year revenue of the startup company up to NTD 810,000,000

|

2022

- To sell the product to two world-famous automobile component manufacturers - Reach an expected annual revenue of NT$ 370 million

|

![]() Market Barriers

Market Barriers

From a technical perspective, spiral bevel gears and hypoid gears are critical components for the transmission of intersecting and interlacing axes; thus, the technical requirements for designing and manufacturing corresponding machines are high.

Domestic gear manufacturers have primarily relied on using expensive foreign machines. However, such machines cannot integrate with domestically developed cloud and IoT systems. If the industry continues to depend on machine tools imported from overseas, then it will not be able to leverage Taiwan’s advantages in back-end cloud computing and IoT in the field of precision machinery. The key to the success of this project is the integration of high-end technical software and hardware.This project invites scholars from several universities and legal persons with more than 15 years of experience in whole-machine and component design and analysis to jointly develop a machine model at lower cost than currently available models but featuring the same level of processing accuracy and a user-friendly human–machine interface. Developed using the research team’s key technologies, including the double-sided double cutting method of gears, the standing machine design, a smart numerical control path, adaptive cutting force, and a virtual–physical integration system, the product is aimed to eventually become commercially available. To adopt the state-of-the-art and highly efficient gear processing software technology proposed by the AIM-HI team, the designed product must use a new configuration that is distinctively different from that of machines that are currently available on the market; this becomes a key highlight to break the market barriers of hypoid gear processing.

![]() Expected Market Size

Expected Market Size

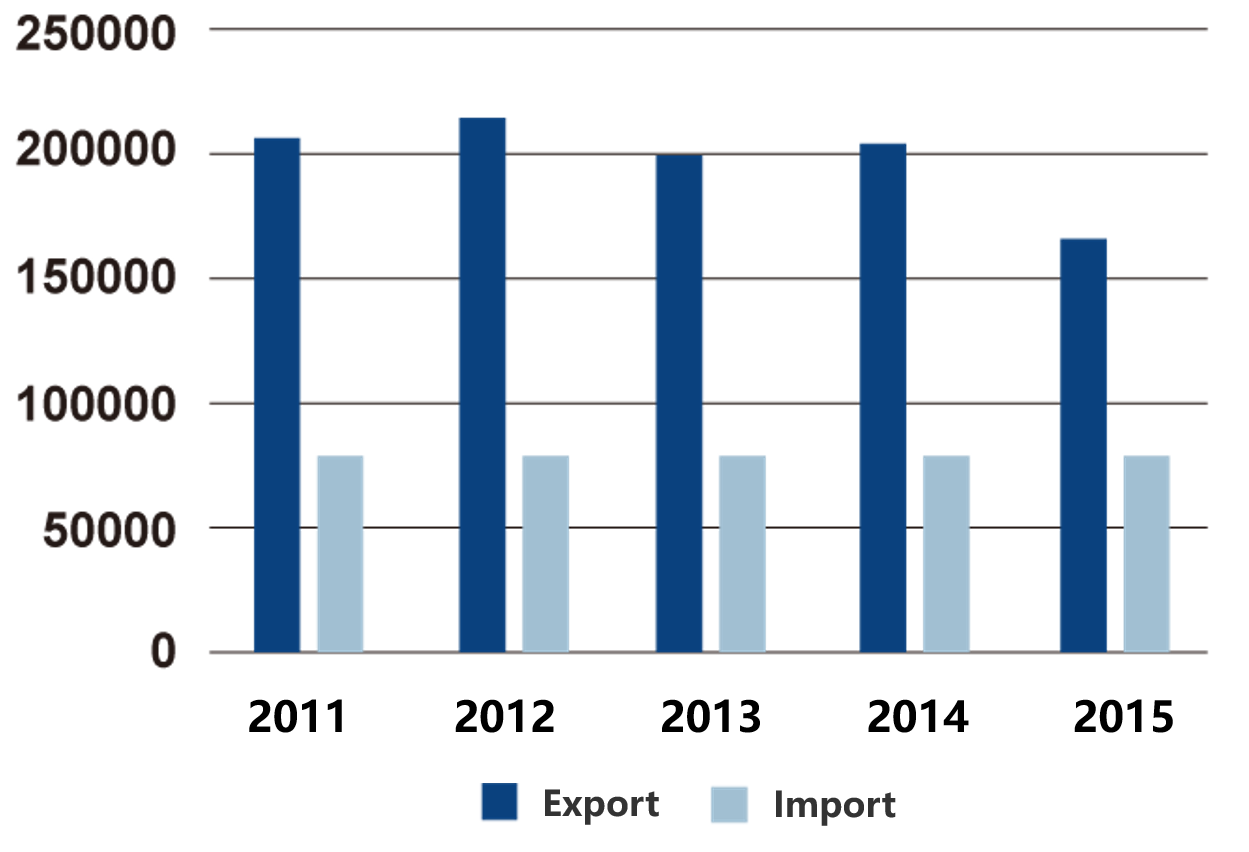

Based on the data compiled by the Taiwan Machine Tool & Accessory Builders’ Association

The cumulative value of metal cutting machine tool exports in 2015 was approximately NT$ 84.7 billion, of which gear-cutting machine tools accounted for approximately 6.3%. Figure 4 presents the import and export values of gear-cutting machines, which were NT$ 1.7 billion and NT$ 5.4 billion in 2015 when USD was converted into NTD at a rate of 32:1, respectively. The European Association of the Machine Tool Industries reported that the total 2015 export value of machine tools in Europe was approximately €18.6 billion. Therefore, the export value of gear-cutting machines, which accounted for 6% in that industry, was €1.2 billion. The gear-cutting machines exported from Taiwan were mostly conventional machines without the feature of numerical control. By contrast, the machine models imported to Taiwan were mainly those with the feature of numerical control, of which hypoid and bevel gear processing machines from Europe and the United States comprised the majority. Depending on the functions and value-added software selected, the machines cost between NT$ 2.5 and 40 million. After the completion of this development project, the market price of the developed machine is expected to be 50%–60% that of imported machines. Focusing on a high cost–performance ratio as a sales strategy, the developed machine is expected to achieve 30% of the domestic market share within 5 years and more than 5% of the global market share for hypoid gear machines.

Taiwan: planing, inserting, pulling, and gear-cutting machine tools

| Unit: US$ 1,000 | 2011 | 2012 | 2013 | 2014 | 2015 |

|---|---|---|---|---|---|

| Export | 207,903 | 214,663 | 199,234 | 205,097 | 166,905 |

| Import | 79,021 | 64,744 | 52,127 | 63,188 | 52,115 |

Source: Machine Tool & Accessory Magazine

Taiwan’s import and export values of gear-cutting machines 2011–2015

621301 Innovation Building R209, 168 University Road, Ming-Hsiung Township, Chia-Yi 621, Taiwan, ROC

621301 Innovation Building R209, 168 University Road, Ming-Hsiung Township, Chia-Yi 621, Taiwan, ROC Tel:(05)2720411#16464 | Fax:05-272-1101

Tel:(05)2720411#16464 | Fax:05-272-1101 E-mail:aimhi@ccu.edu.tw

E-mail:aimhi@ccu.edu.tw